Decommission of two Paper Lines

The Approach

As part of restructure, Kimberly Clark, Northfleet disposed of two of its paper machines to allow one tissue machine to on site to increase its output by 20% and to create space for further operations.

This project took place in two phases, April & September 2021. As the incumbent, Countrystyle were in the best position to manage the segregation required to ensure maximum rebate opportunity of the metals recovered.

Project Management

Countrystyle Recycling, as part of their Major Projects strategy provided Total Project Waste Management throughout the duration of the works.

Countrystyle Recycling ensure correct segregation across various contractors employed by Kimbelry Clark to de-commission both machines.

The dedicated Key Accounts team were available throughout the works, working in line with the de-commissioning contractors 24/7 to ensure the project deadline was reached.

Countrystyle has assisted us over the years to significantly improve our recycling rates, and work towards sustaining the environments that are important to our clients

- Floplast

Countrystyle has assisted us over the years to significantly improve our recycling rates, and work towards sustaining the environments that are important to our clients

- Floplast

Countrystyle has assisted us over the years to significantly improve our recycling rates, and work towards sustaining the environments that are important to our clients

- Floplast

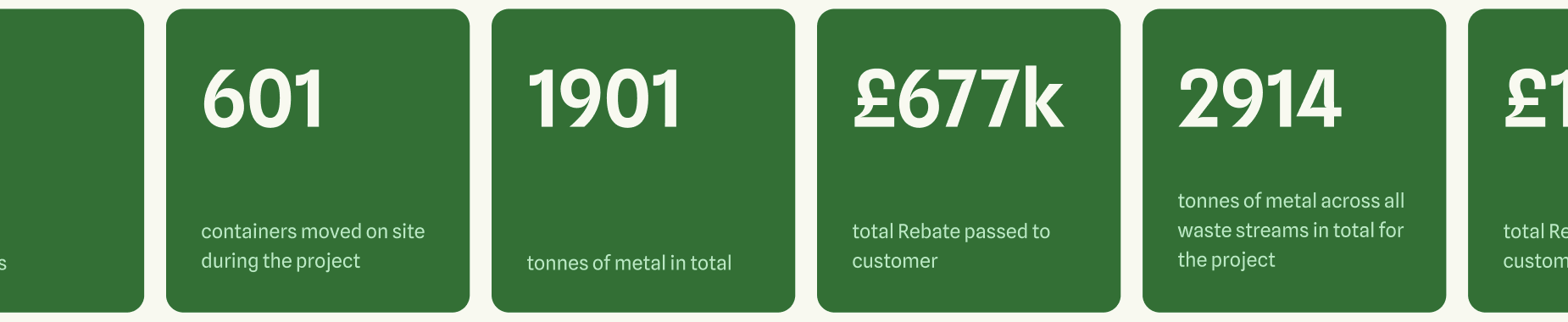

Results

Countrystyle Recycling, using their extensive knowledge of the waste industry diverted all avoidable wastes from landfill, moving incidental construction waste through Permitted Wash Plants, creating sands, gravels and 6F5.

These fractions were then repurposed to be reused back into industry. The remaining waste streams were diverted through picking lines to extract plastics, textiles, and other fractions to be baled into RDF.